Transformer Kering SGOB 400kva minangka solusi sing dipercaya, efisien, lan ramah lingkungan kanggo distribusi tenaga industri. Kapabilitas nangani daya sing kuat, insulasi jinis garing, lan pilihan sing bisa disesuaikan dadi pilihan sing luar biasa kanggo industri sing pengin nambah efisiensi energi, nyuda biaya operasional, lan nyuda jejak lingkungan. Apa ing pabrik manufaktur, operasi panyulingan, utawa aplikasi mesin tugas abot, Transformer Kering SGOB 400kva minangka bukti kemajuan paling anyar ing teknik listrik, menehi kinerja lan linuwih sing ora ana tandhingane.

The SGOB 400kva Dry Transformer is a sophisticated piece of electrical equipment engineered to meet the rigorous demands of industrial, commercial, and institutional sectors. With a power rating of 400 kilovolt-amperes (kva), this transformer offers a reliable, efficient, and environmentally friendly solution for a wide range of power distribution applications.

The SGOB 400kva Dry Transformer, produced by a reputable manufacturer and supplier in China, represent the pinnacle of electrical engineering excellence. These transformers are engineered with precision and cutting-edge technology to provide robust, efficient, and long-lasting power solutions. As a leading manufacturer and supplier in the industry, the company guarantees the highest standards of quality control, ensuring that each SGOB 400kva Dry Transformer meets or exceeds international specifications and client expectations. Suitable for a wide range of applications, these transformers are designed to enhance the reliability and efficiency of power distribution systems globally.

FITUR PRODUK

Transformer Kering 400kva resin epoksi sing diprodhuksi dening Shanghai Industrial Transformer Co., Ltd. dikembangake lan dirancang kanthi kerjasama karo Institut Riset Transformer Shenyang kanthi ngenalake teknologi asing sing maju. Indeks linuwih produk wis tekan tingkat majeng internasional.

SGOB 400kva Garing Transformer aman, flame-retardant lan geni-bukti, polusi-free, lan bisa langsung diinstal ing tengah mbukak. Iku bebas pangopènan, gampang kanggo nginstal, biaya operasi lengkap kurang, mundhut kurang, kinerja Kelembapan-bukti apik, bisa operate biasane ing 100% asor, lan bisa sijine menyang operasi tanpa wis garing sawise mati. Wis discharge sebagean kurang, gangguan kurang, fungsi boros panas kuwat, lan bisa operate ing 150% dirating mbukak ing kahanan cooling online dipeksa.

Transformer Kering SGOB 400kva saiki akeh digunakake ing bangunan dhuwur, pusat komersial, bandara, stasiun, dermaga, subway, pabrik, stasiun distribusi lemah, platform pengeboran minyak lepas pantai, pembangkit listrik lan papan liyane kanthi lingkungan sing atos lan kahanan panggunaan.

Bahan lan fitur utama

Koil nggunakake kabel tembaga terisolasi kelas F minangka konduktor lan serat kaca lan bahan komposit resin epoksi minangka insulasi. Koefisien ekspansi cedhak karo konduktor tembaga lan nduweni resistensi dampak sing apik, resistensi owah-owahan suhu lan resistensi retak. Kabeh komponen serat kaca lan resin epoksi bisa mateni dhewe lan ora bakal terus diobong. Ing wektu sing padha, kumparan voltase dhuwur dibuwang nganggo resin epoksi ing kahanan vakum 1mbar, lan ora ana umpluk ing jero kumparan, supaya discharge parsial kumparan cilik. Ing wektu sing padha, mundhut trafo dikurangi kanthi efektif.

Inti wesi saka trafo digawe saka 30EH120 seri saka dhuwur-permeabilitas kadhemen-mbalek lembaran baja silikon karo orientasi gandum tertib diimpor saka Nippon Steel, Japan, karo 45 ° joints full-bevel lan papat-tingkat langkah-langkah dening-stacking. Lumahing inti wesi disegel karo cat resin insulating kanggo nyegah kelembapan lan karat, lan loro clamps lan fasteners duwe lapisan protèktif anti-karat. Inti wesi kabeh nganggo rakit wesi sing ora ditumpuk lan struktur piring tarik baja, sing kanthi efektif nyuda mundhut tanpa beban, arus tanpa beban lan gangguan inti wesi.

Kanggo voltase kurang lan kumparan saiki dhuwur, kaku short circuit gedhe nalika short circuit occurs, lan nomer voltase kurang dadi cilik. Sing luwih gedhe saiki voltase kurang, luwih penting masalah ampere-giliran ora stabil nalika jinis kabel nduwurke tumpukan digunakake. Masalah boros panas uga kudu dipikirake. Ing wektu iki, nggunakake foil nduwurke tumpukan kanggo voltase kurang luwih bisa ngatasi masalah ing ndhuwur. Kaping pisanan, produk foil ora duwe giliran sumbu lan sudut spiral nduwurke tumpukan aksial. Ing ampere-giliran saka dhuwur lan kurang voltase windings imbang, lan kaku sumbu trafo cilik nalika short circuit occurs. Kapindho, amarga insulasi sing tipis, saluran udara multi-lapisan bisa disetel ing bakal ing proses, lan masalah boros panas uga luwih apik ditanggulangi. Welding internal coil nganggo welding proteksi xenon ing mesin nduwurke tumpukan foil otomatis, sing nduweni presisi dhuwur, resistance welding kurang, lan ora ana proses welding eksternal. Insulasi DMD digunakake ing antarane lapisan nduwurke tumpukan, lan ujunge disegel lan diobati nganggo resin sawise digulung.

The cross-aliran ndhuwur-ndamu cooling penggemar diadopsi, kang nduweni ciri saka gangguan kurang, tekanan angin dhuwur, katon ayu, etc, lan nambah kapasitas overload saka trafo. Kontrol suhu nganggo pengontrol suhu sing cerdas kanggo nambah safety lan linuwih operasi trafo.

DESKRIPSI PRODUK

Epoxy resin terisolasi jinis garing trafo produk banget aman. Bisa langsung diinstal ing tengah mbukak. Kerjane kanthi apik ing lingkungan kelembapan 100% tanpa pangatusan sadurunge. Wis akeh digunakake ing lapangan konstruksi, pusat komersial, bandara, stasiun, pelabuhan, subway, pabrik, stasiun distribusi daya lemah, platform pengeboran minyak lepas pantai, pembangkit listrik dll.

FITUR PRODUK

● Tahan geni

● Kelembapan resistance

● pangopènan lan instalasi gampang

● Mlaku kanthi apik sajrone kahanan lingkungan sing atos

● Produk non-polusi

● Low mundhut sak operasi lengkap

PARAMETER

| MODEL | Ora LOAD LOAD (W) |

MOTO LOSS (120%) |

IMPENDENCE (%) |

NOLOAD SAIKI (%) |

TINGKAT SUMUT (Lpa) dB |

BOOT (KG) |

| SC(B)10-30/10 | 205 | 750 | 4 | 2.3 | 57 | 290 |

| SC(B)10-50/10 | 285 | 1060 | 2.2 | 57 | 360 | |

| SC(B)10-80/10 | 380 | 1460 | 1.7 | 59 | 590 | |

| SC(B)10-100/10 | 410 | 1670 | 1.7 | 59 | 640 | |

| SC(B)10-125/10 | 470 | 1960 | 1.5 | 60 | 670 | |

| SC(B)10-160/10 | 550 | 2250 | 1.5 | 60 | 870 | |

| SC(B)10-200/10 | 650 | 2680 | 1.3 | 61 | 1040 | |

| SC(B)10-250/10 | 740 | 2920 | 1.3 | 61 | 1220 | |

| SC(B)10-315/10 | 880 | 3670 | 1.1 | 63 | 1470 | |

| SC(B)10-400/10 | 1000 | 4220 | 1.1 | 63 | 1760 | |

| SC(B)10-500/10 | 1180 | 5170 | 1.1 | 64 | 2050 | |

| SC(B)10-630/10 | 1300 | 6310 | 6 | 0.9 | 65 | 2360 |

| SC(B)10-800/10 | 1540 | 7360 | 0.9 | 65 | 2730 | |

| SC(B)10-1000/10 | 1750 | 8610 | 0.9 | 65 | 3270 | |

| SC(B)10-1250/10 | 2030 | 10260 | 0.9 | 67 | 3840 | |

| SC(B)10-1600/10 | 2700 | 12400 | 0.9 | 68 | 4920 | |

| SC(B)10-2000/10 | 3000 | 15300 | 0.7 | 70 | 5780 | |

| SC(B)10-2500/10 | 3500 | 18180 | 0.7 | 71 | 6600 | |

| SC(B)10-3150/10 | 4000 | 18800 | 0.5 | 71 | 7800 | |

| SC(B)10-4000/10 | 4700 | 22000 | 0.5 | 76 | 10000 |

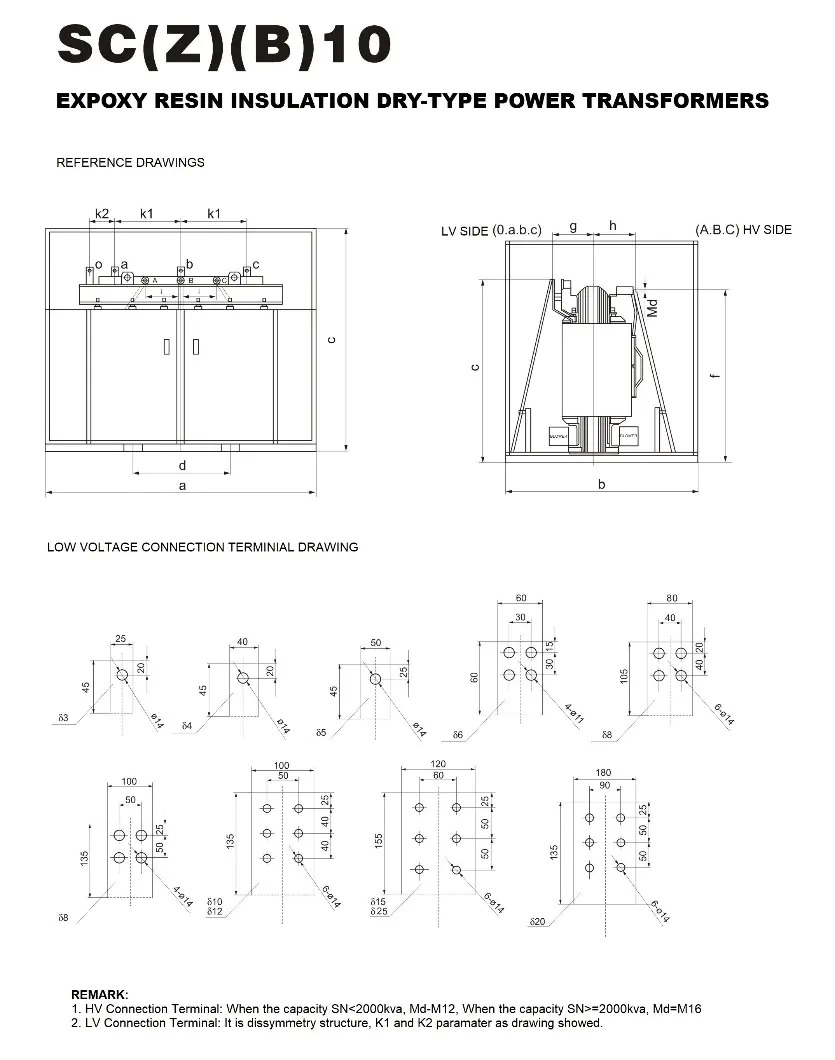

| MODEL | DIMENSION(MM) | |||||||||

| a | b | c | d | e | f | g | h | K1 | K2 | |

| SC(Z)(B) 10-30/10 | 1120 | 850 | 1100 | 400 | 750 | 640 | 290 | 260 | 270 | 135 |

| SC(Z)(B) 10-50/10 | 1170 | 850 | 1160 | 400 | 810 | 700 | 310 | 270 | 290 | 145 |

| SC(Z)(B)10-80/10 | 1210 | 900 | 1240 | 450 | 890 | 760 | 320 | 280 | 290 | 145 |

| SC(Z)(B)10-100/10 | 1240 | 900 | 1280 | 450 | 940 | 880 | 320 | 275 | 295 | 142.5 |

| SC(Z)(B)10-125/10 | 1270 | 950 | 1330 | 550 | 980 | 920 | 325 | 280 | 310 | 155 |

| SC(Z)(B)10-160/10 | 1310 | 1100 | 1360 | 550 | 1010 | 960 | 305 | 260 | 315 | 157.5 |

| SC(Z)(B)10-200/10 | 1350 | 1140 | 1400 | 660 | 1050 | 980 | 310 | 265 | 340 | 170 |

| SC(Z)(B)10-250/10 | 1420 | 1210 | 1430 | 660 | 1075 | 1010 | 300 | 255 | 355 | 177.5 |

| SC(Z)(B)10-315/10 | 1460 | 1250 | 1460 | 660 | 1100 | 1050 | 305 | 260 | 365 | 182.5 |

| SC(Z)(B)10-400/10 | 1520 | 1280 | 1520 | 660 | 1165 | 1090 | 315 | 270 | 375 | 187.5 |

| SC(Z)(B)10-500/10 | 1530 | 1320 | 1580 | 660 | 1205 | 1150 | 320 | 275 | 385 | 182.5 |

| SC(Z)(B)10-630/10 | 1670 | 1350 | 1630 | 660 | 1280 | 1200 | 325 | 280 | 430 | 215 |

| SC(Z)(B)10-800/10 | 1680 | 1350 | 1650 | 820 | 1300 | 1220 | 340 | 295 | 445 | 222.5 |

| SC(Z)(B)10-1000/10 | 1770 | 1420 | 1750 | 820 | 1390 | 1310 | 345 | 300 | 465 | 232.5 |

| SC(Z)(B)10-1250/10 | 1880 | 1530 | 1790 | 820 | 1430 | 1350 | 355 | 310 | 485 | 242.5 |

| SC(Z)(B)10-1600/10 | 1960 | 1530 | 1860 | 1070 | 1520 | 1420 | 375 | 330 | 510 | 255 |

| SC(Z)(B)10-2000/10 | 2000 | 1620 | 1960 | 1070 | 1600 | 1500 | 395 | 350 | 510 | 255 |

| SC(Z)(B)10-2500/10 | 2100 | 1680 | 2040 | 1070 | 1680 | 1560 | 425 | 380 | 550 | 275 |

| SC(Z)(B)10-3150/10 | 2240 | 1750 | 2150 | 1070 | 1800 | 1660 | 460 | 410 | 580 | 290 |

| SC(Z)(B) 10-4000/10 | 2370 | 1840 | 2310 | 1070 | 1960 | 1800 | 500 | 450 | 630 | 315 |

| MODEL | CAPACITY (KVA) | LENGKA (MM) |

WIDTH (MM) | Dhuwur (MM) |

LONGITUDINAL (MM) | HORIZONTAL (MM) | BOOT (KG) |

| SC(Z)(B) 10-30/10 | 30 | 770 | 500 | 750 | 400 | 450 | 285 |

| SC(Z)(B) 10-50/10 | 50 | 820 | 500 | 810 | 400 | 450 | 330 |

| SC(Z)(B)10-80/10 | 80 | 860 | 550 | 890 | 450 | 500 | 465 |

| SC(Z)(B)10-100/10 | 100 | 890 | 650 | 940 | 450 | 600 | 530 |

| SC(Z)(B)10-125/10 | 125 | 920 | 650 | 980 | 550 | 600 | 640 |

| SC(Z)(B)10-160/10 | 160 | 960 | 800 | 1010 | 550 | 750 | 760 |

| SC(Z)(B)10-200/10 | 200 | 1000 | 800 | 1050 | 660 | 750 | 905 |

| SC(Z)(B)10-250/10 | 250 | 1070 | 900 | 1075 | 660 | 850 | 1085 |

| SC(Z)(B)10-315/10 | 315 | 1110 | 900 | 1100 | 660 | 850 | 1175 |

| SC(Z)(B)10-400/10 | 400 | 1170 | 900 | 1165 | 660 | 850 | 1460 |

| SC(Z)(B) 10-500/10 | 500 | 1180 | 970 | 1205 | 660 | 920 | 1670 |

| SC(Z)(B) 10-630/10 | 630 | 1320 | 1000 | 1280 | 660 | 950 | 1890 |

| SC(Z)(B)10-800/10 | 800 | 1325 | 1000 | 1300 | 820 | 950 | 2320 |

| SC(Z)(B)10-1000/10 | 1000 | 1420 | 1180 | 1390 | 820 | 950 | 2800 |

| SC(Z)(B)10-1250/10 | 1250 | 1530 | 1320 | 1430 | 820 | 1270 | 3255 |

| SC(Z)(B)10-1600/10 | 1600 | 1610 | 1320 | 1520 | 1070 | 1270 | 4115 |

| SC(Z)(B) 10-2000/10 | 2000 | 1650 | 1500 | 1600 | 1070 | 1450 | 4690 |

| SC(Z)(B)10-2500/10 | 2500 | 1750 | 1550 | 1680 | 1070 | 1500 | 5620 |

| SC(Z)(B) 10-3150/10 | 3150 | 1890 | 1550 | 1800 | 1070 | 1500 | 6850 |

| SC(Z)(B) 10-4000/10 | 4000 | 2020 | 1630 | 1960 | 1070 | 1580 | 8110 |

PROFIL PERUSAHAAN

Shanghai Industry Transformers Co., Ltd (SGOB) minangka pemasok peralatan distribusi listrik lengkap. Produk kita kalebu:

● Trafo kacemplungaken lenga

● 35KV trafo kacemplungaken lenga

● Expoxy resin jampel garing-jinis trafo daya

● Transformer distribusi paduan amorf

● trafo photovoltaic

● trafo daya angin

● Box-style substation transformers

Perusahaan kita didegake ing taun 2007 lan saiki duwe bengkel 40,000sqm lan luwih saka 200 karyawan. Produk kita akeh digunakake ing macem-macem industri kayata pembangkit listrik lan distribusi, produksi batu bara, metalurgi, minyak lan gas, bahan kimia, konstruksi, pelabuhan, bandara, sepur lan infrastruktur kotamadya.

Kita uga gawé peralatan sing gegandhengan kayata lemari listrik lan enclosures, kothak switchgear Saiki, kita ngembangaken baris produk kita menyang wilayah-related daya liyane kaya konektor shrink panas, kabel listrik lan peralatan mechanical gadhah etc. Kita goal kanggo mbangun siji-mandeg peralatan listrik lan platform sumber bagean kanggo basis pelanggan global kita.

Kita ngandelake sistem kontrol kualitas sing ketat kanggo ngirim produk kanthi kualitas sing paling dhuwur. Saka 200 karyawan, 46 minangka pengalaman insinyur. Sistem kualitas kita kalebu kualifikasi kanggo:

● National Transformers Quality Supervision Center of China

● Sistem Manajemen Mutu ISO-9001:2008

● ISO-14001:2004 Sistem Manajemen Lingkungan

● Sistem Kesehatan lan Keamanan OHSMS18000

Paten kita:

Kapabilitas tes produksi lan kualitas kalebu:

● Penggulungan foil otomatis

● Digital silikon baja sheeting lan slitting

● Kanthi otomatis vakum pangatusan open lan baris varnish

● HAEFLY discharge sebagean tester

● HAEFLY daya analyzer

● HAEFLY harmonik analyzer

Asil kasebut minangka produk efisiensi dhuwur, boros daya sing luwih murah lan swara sing sithik kanggo nggedhekake investasi infrastruktur sampeyan.